Pre-stressing Works – Overview

PRESTRESS CONCRETE

PRESTRESS CONCRETE

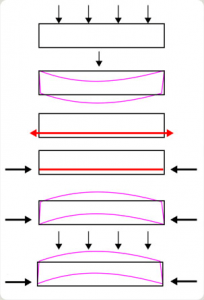

Prestressed concrete is basically concrete in which internal stresses of a suitable magnitude and distribution are introduced so that the stresses resulting from external loads are counteracted to a desired degree. In reinforced concrete member, the prestress is commonly introduced by tensioning the steel reinforcement.

The application of permanent compressive stress to a material like concrete, which is strong in compression but weak in tension, increases the apparent tensile strength of that material, because the subsequent application of tensile stress must first nullify compressive prestress.

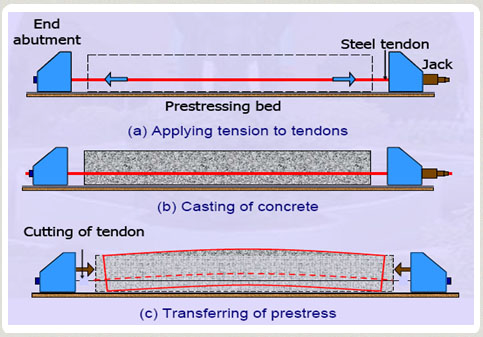

PRE – TENSIONING

A method of prestressing concrete in which the tendons are tensioned before concreting. Pre-tensioning is done by stressing a wire, strand or bar, PRIOR to concreting. As these stressed elements are embedded and bonded in the concrete, no anchorages are required to hold back the tension forces in it.

Pre-tensioning is predominantly done in precast yards. End blocks supported by piles are required to be erected to hold back these pre stressing forces.

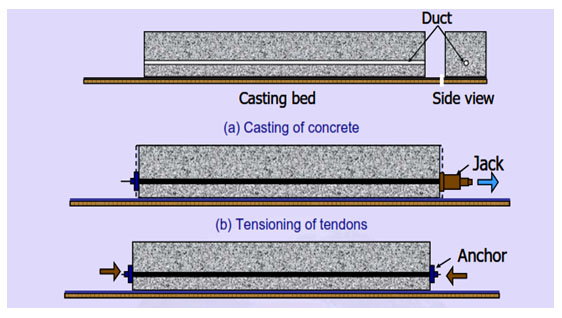

POST – TENSIONING

A method of prestressing concrete in the prestessing steel is tensioned against the hardened concrete. For post-tensioning, wire, strand or bar is installed and stressed to its intended forces AFTER concreting has taken place. Anchorages and wedges are used to hold back the forces.

This method statement has been developed to provide guidance for all personnel involved in the project in using UPS systems which covers the installation, stressing and grouting operations.

MATERIAL: Strand:

Strand is manufactured from 7 individual cold-drawn wires, outer wires helically wound around one center wire (king wire) as per IS code (IS14268:1995). Strand coatings do not affect the anchorage‘s capacity or efficiency. For improved corrosion protection we offer systems using galvanized iron ducts. The strand should be stored in clean and dry place. There are two different types of strand i.e. 0.5” and 0.6”.

| Strands | 0.50 inches | 0.60 inches |

| Nominal Diameter | 12.7mm | 15.24mm |

| Nominal Area | 100mm2 | 140mm2 |

| Nominal Weight | 0.775kg/m | 1.102kg/m |

| Tensile Strength | 1860N/mm2 | 1860N/mm2 |

| Modulus of elasticity | 195kN/mm2 | 195kN/mm2 |

| Min breaking load of strand | 183.7kN | 260.7kN |

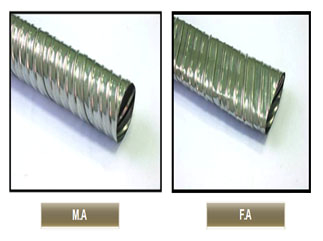

SHEATHINGS

The sheathings for bonded tendons shall be spirally wound galvanized steel tubing made from galvanized steel strips of 0.3 mm thickness.

The sheathings for bonded tendons shall be spirally wound galvanized steel tubing made from galvanized steel strips of 0.3 mm thickness.

The sheathings shall be mortar tight to prevent entrance of cement grout during concreting and shall be corrugated for better bonding.

The sheathings shall be sufficiently strong to retain shapes and to resist damages during construction.

The round sheathings with various outer diameters from 68mm to 135mm have been widely used in UPS Multiplane anchorage systems.

The sheathings used flat anchorage system shall be oval in shape with the dimension of 80 mm in width and 25 mm depth for accommodating 5nos of strand and 54 mm in width, 25mm depth for accommodating 3nos of strand.

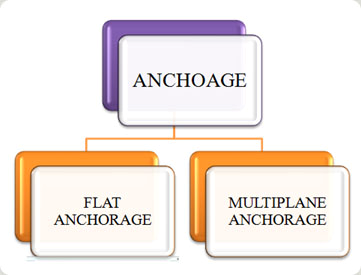

ANCHORAGES

The prestressing force is transferred to the concrete at the anchorage. Anchorage where the stressing take places are called active anchorage, and the other are called passive anchorage. Sometimes stressing is made from both ends of a tendon to reduce friction losses. The anchorage shall be safe and secure against both dynamic and static loads as well as impact.

The prestressing force is transferred to the concrete at the anchorage. Anchorage where the stressing take places are called active anchorage, and the other are called passive anchorage. Sometimes stressing is made from both ends of a tendon to reduce friction losses. The anchorage shall be safe and secure against both dynamic and static loads as well as impact.

The anchoring device shall be strong enough to resist in all respect a force equal to at least breaking strength of the prestressing tendons.